当法国应对快速蔓延的新冠病毒大流行时,总统埃马纽埃尔·马克龙在全国讲话中宣布:“我们正处于战争中。”

法国总统并不是唯一一位把疫情作比战时状态的政治家。英国首相鲍里斯·约翰逊称病毒是“致命的敌人”,必须战胜它。风险投资家也为成为“战时CEO”的企业家们提供了建议。

此外,努力号召工业界抗击新冠病毒的做法——从汽车制造商用工厂线制造呼吸机,到时尚品牌改用织布机生产口罩——以及有关定量配给卫生纸、面粉等生活必需品的谈论,都引发了人们对于二战期间经济转型的回忆。在那个年代,工业界(特别在美国)协助政府建立起“民主国家的兵工厂”,生产了成千上万辆坦克、飞机和轮船,而广泛使用的定量配给和价格控制政策也起到了防止囤货居奇的作用。

但二战经验和新冠病毒大流行的相关性究竟有多大呢?从当年成功管控工业的做法中,政府应该借鉴哪些经验呢?

研究1940年代战时经济的历史学家们表示,虽然那个年代和当下的情况有显著区别,但在这场危机中,政府仍然可以借鉴某些政策。

统一协调供应

北卡罗来纳大学夏洛特分校的历史学教授马克·威尔逊认为,第一个,或许也是最重要的经验,就是在协调生产和为企业提供正确的激励措施方面,政府发挥着至关重要的作用。

威尔逊是2017年出版的《破坏性创造:美国企业与第二次世界大战的胜利》一书的作者。他说,美国在珍珠港事件后立即成立了战时生产委员会,用以协调重要军需物资的生产事宜,作为统一协调机构,领导各地全力提升轮船、飞机和弹药的产量。

这正是让威尔逊觉得奇怪的地方,因为随着美国爆发新冠病毒疫情,联邦政府有时似乎放弃了协调物资采购的职责。美国总统唐纳德·特朗普迟迟未启动《国防生产法案》,该法案允许他命令企业为政府生产医疗用品,还可扣押出口或私人客户的物资。据报道,美国商会曾游说特朗普不要启用这项法律。上周四,特朗普终于援引该法案,加快生产呼吸机。此外,他还阻止了外科口罩制造商3M向海外出口医疗物资,并下令“截胡”了一批运往德国的口罩。

特朗普还曾告诉各州,购买呼吸机和防护设备主要靠自己。3月16日,特朗普在与州长们的电话会议上表示:“你们要试着靠自己去采购呼吸器、呼吸机等所有设备。”本周,因所在州医院的物资严重不足,备感绝望的纽约州长安德鲁·科莫不得不向联邦政府寻求援助。他说:“在此刻,一个州唯一的希望真的只能来自联邦政府。”

更糟糕的是,因缺乏联邦政府的协调,美国各州被迫要抢购关键设备和物资——由此推高了产品价格。威尔逊称,美国从内战期间的痛苦经历吸取了教训:各州最初基本上都是自己准备军备,因而产生了很大的问题。就像现在一样,各州因急于争夺稀缺物资而推升了价格,“导致纽约州等更大、更富裕的州和印第安纳州等比较贫穷的州,在军队方面拉开了很大差距。”

“让我感到震惊的是,160年过去了,我们还是没能吸取教训,”威尔逊说道。

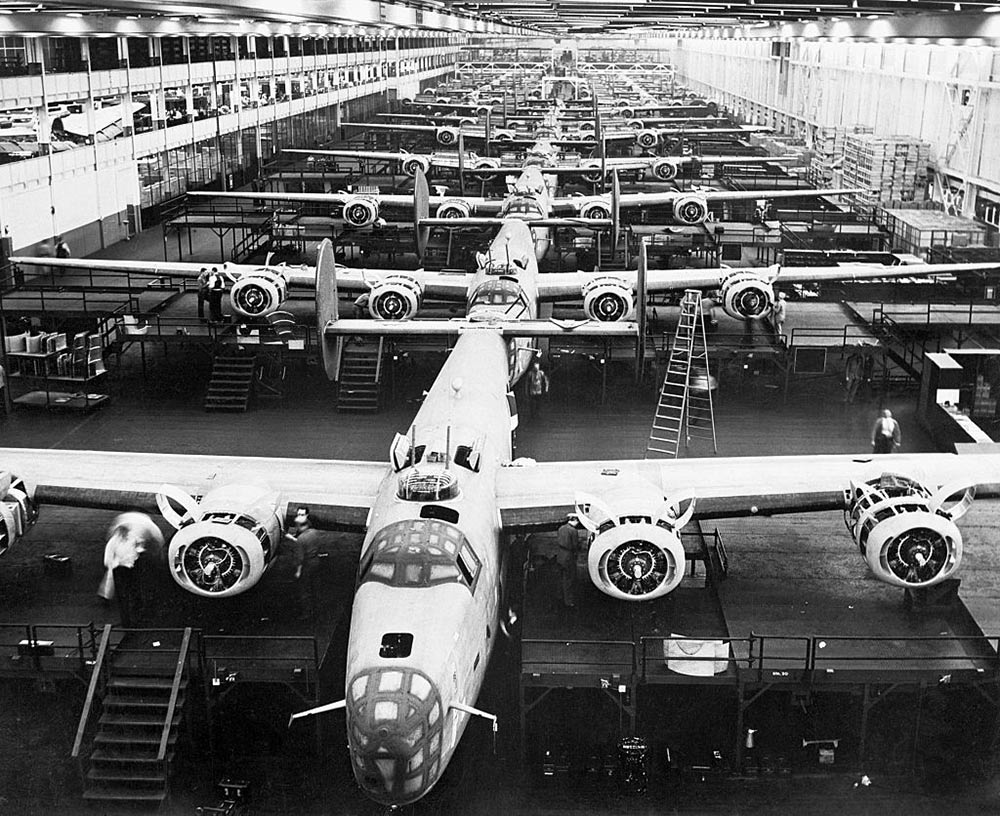

1943年,福特汽车公司在底特律的Willow Run工厂组装B-24“解放者”轰炸机。历史学家发现,政府动员企业进行战时生产的某些做法,可能有助于号召企业抗击新冠病毒。图片来源:Ford/Getty Images

1943年,福特汽车公司在底特律的Willow Run工厂组装B-24“解放者”轰炸机。历史学家发现,政府动员企业进行战时生产的某些做法,可能有助于号召企业抗击新冠病毒。图片来源:Ford/Getty Images政府在二战期间也进行过干预,避免有的州在采购重要医疗设备时遭遇哄抬物价的问题。军队和民众都需要的多种物资——比如糖类、汽油和鞋类——都受到定量配给和明确价格政策的管控。

威尔逊表示,政府在二战时期的大部分合同都依照成本加成原则签订,这样做既能鼓励供应商生产所需商品——因为可保障他们获得利润,也能把盈利限制在适中水平。事实上,在与军事供应商签署的大多数合同中,政府都坚持加入了回拨条款(clawback),以便能追回超额利润。军事合同的回拨条款一直沿用至朝鲜战争结束。更重要的是,政府设定了极高的税率——在某些情况下,可高达公司“超额利润”的90%。

许多二战政策都是根据美国人在一战期间的经验制定的。当时,美国工业公司纷纷攫取“战争暴利”,在战后变成了巨大的丑闻。这次疫情也可能会发生类似的情况,当疾病造成死亡和整体经济低迷时,公众会将愤怒的矛头指向那些向州政府抬高基本医疗用品价格以牟取暴利的公司。根据ProPublica的调查报道,纽约州花费了近25万美元购买一台便携式X光机,而该售价通常介于3万到8万美元之间;此外,该州还花了20美分来购买平时不到5美分的手套。

共享专利

历史学家们认为,另一个从二战工业政策学到的教训是,政府应依靠现有的产品和制造商,与他们携手合作,把设计授权给其他制造商以扩大生产——而不是浪费时间去设计或发明新设备。大卫·埃杰顿是伦敦国王学院的历史学教授,著有《英国战争机器》一书。他说,虽然努力应战确实能激发创新,但大多数新技术都需要数年时间才能得以完善,直到战争接近尾声才可以使用。“二战中采用的大部分技术都来自二战前,”他说。

政府通常会向原创专利持有人和设计者施压,要求他们将产品授权给其他制造商。例如,普惠生产飞机发动机时得到了斯蒂旁克公司和苏联部分工厂的授权,英国劳斯莱斯梅林飞机发动机则经美国Packard Motor Company授权才生产。

埃杰顿担心,当今的政策制定者已经听信了这样的神话——即短短几天内,新技术就能以某种方式神奇地完成起草到部署的全过程。英国首相温斯顿·丘吉尔在战时也曾受此影响。但实际上,即便在战争时期,这一过程也需要花费数年时间。“二战中的大多数采购,都是在扩大生产已采购的物资,”他说。

为了满足目前激增的呼吸机需求,英国政府起初试图说服有兴趣制造设备的生产商做新设计。确实,以真空吸尘器和吹风机闻名的戴森仅用10天就设计了一款全新的呼吸机。但现在,该公司必须获得监管部门审批,如此一来就可能造成使用上的延误。其他制造商则对政府的建议犹豫不决,相反,他们同意获取现有呼吸机制造商的设计许可。

疫情和二战是否有可比性

二战期间,有大量工厂改装车间制造武器。比如,通用汽车工厂停止生产民用车,开始为美国陆军制造卡车,有的黄铜配件厂转而生产弹壳。

但二战时的改装生产可能只是个被过度宣扬的神话。威尔逊说,尽管二战时有的装配线确实进行了改装,但大多数关键武器都是在全新的工厂里生产的。这些工厂由政府出资建造,然后让公司承包经营。他说,那才是为战争制造大部分飞机、坦克和轮船的生产方式。

当然,建造全新的工厂需要耗费几个月时间,而新冠病毒疫情预计将在几周内达到高峰,所埃杰顿认为,将现在的情况与二战时努力生产的情形相比,可能比较肤浅。“必须和二战中的特定事件做类比”——比如敦刻尔克大撤退中动用的民用船——“而不是为战争付出的全部努力。”

英国华威大学的经济史学家马克·哈里森也觉得没有什么可比性。他在个人博客上写道,各国政府最多只有几个月时间为新冠病毒大流行做准备。这与二战时的情况截然不同,在战争爆发前,政府有好几年时间思考如何组织全社会迎战——而且,当时还能借鉴一战的经验。“我们正处于战争中,但手里握着一张白纸,”哈里森在有关新冠疫情的文章中写道。

威尔逊认为,制药业可能是有时间投资新设备的领域。特别是需要大量生产的疫苗,或会对现有产能形成压力。而且,由于疫苗可能至少一年后才问世,因此政府现在就能投资建造新设备,把运营权外包给已有的制药商。

当谈及宏观经济政策时,历史学家认为,当年与现在的危机没有太多相似之处。哈里森写道,二战造成了资本和劳动力需求的爆炸式增长,因此政府的许多政策都以控制通胀为目标。今天的情况却并非如此,许多企业因保持社交距离的措施而倒闭,造成了数百万人失业。

威尔逊认为,目前的情况实际上更接近大萧条时期,因此可能需要采用类似的计划来保障就业和提振需求。他说,美国可能会考虑借鉴富兰克林·罗斯福总统的新政政策,投资基建项目——只是为了让人们重新就业。但另一方面,他也承认,现在需要保持社交距离,这与让更多人复工的政策背道而驰。

历史学家们担心,新冠病毒可能会加剧西方社会已经加速恶化的收入不均问题。哈里森写道,二战“导致成百上千万人死亡、受伤和痛失亲人,但没有人陷入贫困,因为每个人都有自己的角色,也能找到工作。战争结束后,英国社会比以前平等多了。”

但这一次,不太可能出现这样的情形。(财富中文网)

译者:Emily

当法国应对快速蔓延的新冠病毒大流行时,总统埃马纽埃尔·马克龙在全国讲话中宣布:“我们正处于战争中。”

法国总统并不是唯一一位把疫情作比战时状态的政治家。英国首相鲍里斯·约翰逊称病毒是“致命的敌人”,必须战胜它。风险投资家也为成为“战时CEO”的企业家们提供了建议。

此外,努力号召工业界抗击新冠病毒的做法——从汽车制造商用工厂线制造呼吸机,到时尚品牌改用织布机生产口罩——以及有关定量配给卫生纸、面粉等生活必需品的谈论,都引发了人们对于二战期间经济转型的回忆。在那个年代,工业界(特别在美国)协助政府建立起“民主国家的兵工厂”,生产了成千上万辆坦克、飞机和轮船,而广泛使用的定量配给和价格控制政策也起到了防止囤货居奇的作用。

但二战经验和新冠病毒大流行的相关性究竟有多大呢?从当年成功管控工业的做法中,政府应该借鉴哪些经验呢?

研究1940年代战时经济的历史学家们表示,虽然那个年代和当下的情况有显著区别,但在这场危机中,政府仍然可以借鉴某些政策。

统一协调供应

北卡罗来纳大学夏洛特分校的历史学教授马克·威尔逊认为,第一个,或许也是最重要的经验,就是在协调生产和为企业提供正确的激励措施方面,政府发挥着至关重要的作用。

威尔逊是2017年出版的《破坏性创造:美国企业与第二次世界大战的胜利》一书的作者。他说,美国在珍珠港事件后立即成立了战时生产委员会,用以协调重要军需物资的生产事宜,作为统一协调机构,领导各地全力提升轮船、飞机和弹药的产量。

这正是让威尔逊觉得奇怪的地方,因为随着美国爆发新冠病毒疫情,联邦政府有时似乎放弃了协调物资采购的职责。美国总统唐纳德·特朗普迟迟未启动《国防生产法案》,该法案允许他命令企业为政府生产医疗用品,还可扣押出口或私人客户的物资。据报道,美国商会曾游说特朗普不要启用这项法律。上周四,特朗普终于援引该法案,加快生产呼吸机。此外,他还阻止了外科口罩制造商3M向海外出口医疗物资,并下令“截胡”了一批运往德国的口罩。

特朗普还曾告诉各州,购买呼吸机和防护设备主要靠自己。3月16日,特朗普在与州长们的电话会议上表示:“你们要试着靠自己去采购呼吸器、呼吸机等所有设备。”本周,因所在州医院的物资严重不足,备感绝望的纽约州长安德鲁·科莫不得不向联邦政府寻求援助。他说:“在此刻,一个州唯一的希望真的只能来自联邦政府。”

更糟糕的是,因缺乏联邦政府的协调,美国各州被迫要抢购关键设备和物资——由此推高了产品价格。威尔逊称,美国从内战期间的痛苦经历吸取了教训:各州最初基本上都是自己准备军备,因而产生了很大的问题。就像现在一样,各州因急于争夺稀缺物资而推升了价格,“导致纽约州等更大、更富裕的州和印第安纳州等比较贫穷的州,在军队方面拉开了很大差距。”

“让我感到震惊的是,160年过去了,我们还是没能吸取教训,”威尔逊说道。

1943年,福特汽车公司在底特律的Willow Run工厂组装B-24“解放者”轰炸机。历史学家发现,政府动员企业进行战时生产的某些做法,可能有助于号召企业抗击新冠病毒。

政府在二战期间也进行过干预,避免有的州在采购重要医疗设备时遭遇哄抬物价的问题。军队和民众都需要的多种物资——比如糖类、汽油和鞋类——都受到定量配给和明确价格政策的管控。

威尔逊表示,政府在二战时期的大部分合同都依照成本加成原则签订,这样做既能鼓励供应商生产所需商品——因为可保障他们获得利润,也能把盈利限制在适中水平。事实上,在与军事供应商签署的大多数合同中,政府都坚持加入了回拨条款(clawback),以便能追回超额利润。军事合同的回拨条款一直沿用至朝鲜战争结束。更重要的是,政府设定了极高的税率——在某些情况下,可高达公司“超额利润”的90%。

许多二战政策都是根据美国人在一战期间的经验制定的。当时,美国工业公司纷纷攫取“战争暴利”,在战后变成了巨大的丑闻。这次疫情也可能会发生类似的情况,当疾病造成死亡和整体经济低迷时,公众会将愤怒的矛头指向那些向州政府抬高基本医疗用品价格以牟取暴利的公司。根据ProPublica的调查报道,纽约州花费了近25万美元购买一台便携式X光机,而该售价通常介于3万到8万美元之间;此外,该州还花了20美分来购买平时不到5美分的手套。

共享专利

历史学家们认为,另一个从二战工业政策学到的教训是,政府应依靠现有的产品和制造商,与他们携手合作,把设计授权给其他制造商以扩大生产——而不是浪费时间去设计或发明新设备。大卫·埃杰顿是伦敦国王学院的历史学教授,著有《英国战争机器》一书。他说,虽然努力应战确实能激发创新,但大多数新技术都需要数年时间才能得以完善,直到战争接近尾声才可以使用。“二战中采用的大部分技术都来自二战前,”他说。

政府通常会向原创专利持有人和设计者施压,要求他们将产品授权给其他制造商。例如,普惠生产飞机发动机时得到了斯蒂旁克公司和苏联部分工厂的授权,英国劳斯莱斯梅林飞机发动机则经美国Packard Motor Company授权才生产。

埃杰顿担心,当今的政策制定者已经听信了这样的神话——即短短几天内,新技术就能以某种方式神奇地完成起草到部署的全过程。英国首相温斯顿·丘吉尔在战时也曾受此影响。但实际上,即便在战争时期,这一过程也需要花费数年时间。“二战中的大多数采购,都是在扩大生产已采购的物资,”他说。

为了满足目前激增的呼吸机需求,英国政府起初试图说服有兴趣制造设备的生产商做新设计。确实,以真空吸尘器和吹风机闻名的戴森仅用10天就设计了一款全新的呼吸机。但现在,该公司必须获得监管部门审批,如此一来就可能造成使用上的延误。其他制造商则对政府的建议犹豫不决,相反,他们同意获取现有呼吸机制造商的设计许可。

疫情和二战是否有可比性

二战期间,有大量工厂改装车间制造武器。比如,通用汽车工厂停止生产民用车,开始为美国陆军制造卡车,有的黄铜配件厂转而生产弹壳。

但二战时的改装生产可能只是个被过度宣扬的神话。威尔逊说,尽管二战时有的装配线确实进行了改装,但大多数关键武器都是在全新的工厂里生产的。这些工厂由政府出资建造,然后让公司承包经营。他说,那才是为战争制造大部分飞机、坦克和轮船的生产方式。

当然,建造全新的工厂需要耗费几个月时间,而新冠病毒疫情预计将在几周内达到高峰,所埃杰顿认为,将现在的情况与二战时努力生产的情形相比,可能比较肤浅。“必须和二战中的特定事件做类比”——比如敦刻尔克大撤退中动用的民用船——“而不是为战争付出的全部努力。”

英国华威大学的经济史学家马克·哈里森也觉得没有什么可比性。他在个人博客上写道,各国政府最多只有几个月时间为新冠病毒大流行做准备。这与二战时的情况截然不同,在战争爆发前,政府有好几年时间思考如何组织全社会迎战——而且,当时还能借鉴一战的经验。“我们正处于战争中,但手里握着一张白纸,”哈里森在有关新冠疫情的文章中写道。

威尔逊认为,制药业可能是有时间投资新设备的领域。特别是需要大量生产的疫苗,或会对现有产能形成压力。而且,由于疫苗可能至少一年后才问世,因此政府现在就能投资建造新设备,把运营权外包给已有的制药商。

当谈及宏观经济政策时,历史学家认为,当年与现在的危机没有太多相似之处。哈里森写道,二战造成了资本和劳动力需求的爆炸式增长,因此政府的许多政策都以控制通胀为目标。今天的情况却并非如此,许多企业因保持社交距离的措施而倒闭,造成了数百万人失业。

威尔逊认为,目前的情况实际上更接近大萧条时期,因此可能需要采用类似的计划来保障就业和提振需求。他说,美国可能会考虑借鉴富兰克林·罗斯福总统的新政政策,投资基建项目——只是为了让人们重新就业。但另一方面,他也承认,现在需要保持社交距离,这与让更多人复工的政策背道而驰。

历史学家们担心,新冠病毒可能会加剧西方社会已经加速恶化的收入不均问题。哈里森写道,二战“导致成百上千万人死亡、受伤和痛失亲人,但没有人陷入贫困,因为每个人都有自己的角色,也能找到工作。战争结束后,英国社会比以前平等多了。”

但这一次,不太可能出现这样的情形。(财富中文网)

译者:Emily

"We are at war," Emmanuel Macron declared in a national address as France confronted the rapidly spreading coronavirus pandemic.

The French President is not the only politician drawing wartime analogies. U.K. Prime Minister Boris Johnson has spoken of the virus as "a deadly enemy" which must be combated. Venture capitalists too have counseled entrepreneurs on the value of becoming "wartime CEOs."

Certainly efforts to enlist industry in the fight against coronavirus—from automakers converting factory lines to produce ventilators to fashion brands turning looms over to mask production—and talk of rationing essential items, from toilet paper to flour, evoke nothing so much as the transformation of the economy during World War II. That’s when industry, particularly in the U.S., helped build “An Arsenal of Democracy,” churning out tanks, planes and ships by the thousands, and rationing and price-controls were widely used to prevent hoarding.

But how relevant is the Second World War experience to the coronavirus pandemic? Are there lessons governments ought to be drawing on from the way it so successfully harnessed industry back then?

Historians who study the wartime economies of the 1940s say there are significant differences between then and now, but that there are still policies governments could emulate in this crisis.

Supplier-in-chief

The first, and perhaps most important lesson, is that government has a critical role to play in coordinating production and providing the right incentives to business, says Mark Wilson, a history professor at the University of North Carolina Charlotte.

In the U.S., the Wartime Production Board was established immediately after Pearl Harbor to coordinate the manufacture of vital military supplies—and it became the umbrella organization for a number of efforts aimed at boosting the manufacture of ships, planes and ammunition, says Wilson, author of the 2017 book Destructive Creation: American Business and the Winning of World War II.

That’s why Wilson says he found it bizarre that, as the coronavirus outbreak spread in the U.S., the federal government often seemed to abdicate its role in coordinating the procurement of supplies. U.S. President Donald Trump hesitated to invoke the Korean War-era Defense Production Act, which would allow him to order companies to produce medical supplies for the government and to seize supplies bound for export or private customers. The U.S. Chamber of Commerce reportedly lobbied Trump not to invoke the law. On Thursday, Trump finally did invoke the Act to speed the production of ventilators and, in the case of surgical mask manufacturer 3M, he ordered the seizure of a shipment of masks overseas that had been bound for Germany.

Trump has told individual states it is primarily up to them to purchase their own ventilators and protective equipment. “Respirators, ventilators, all of the equipment—try getting it yourselves,” U.S. President Donald Trump said on a conference call with governors on March 16. This week, a desperate New York Governor Andrew Cuomo, his state’s hospitals running critically low on supplies, was left to plead for federal help. “Really, the only hope for a state at this point is the federal government's capacity to deliver,” he said.

Worse, without federal coordination, U.S. states have been forced to bid against one another for vital equipment and supplies—driving up prices. Wilson says the U.S. had learned from bitter experience during the Civil War, when states were at first largely left to equip their own regiments, how problematic this kind of approach can be. Just like now, the states wound up competing for scarce material with one another, driving up prices, and "leading to big disparities between military units from larger, wealthier states, like New York, and poorer ones, like Indiana."

“I am stunned that 160 years later, we failed to learn that lesson,” Wilson says.

In the Second World War, the government also stepped in to prevent the kind of price gouging that some states have encountered when trying to procure vital medical equipment. Many items that were in demand for both the military and the civilian population—such as sugar, gasoline and shoes—were subject to rationing and explicit price controls.

Wilson says that most WWII-era contracts the government handed out were on a cost-plus basis. This encouraged suppliers to produce needed goods, since they were assured of making a profit, but it capped those profits at a modest level. In fact, the government insisted on clawbacks in most contracts with military suppliers that would allow it to claim back any excess profits. These clawbacks persisted in military contracts through to the Korean War. What’s more, the government set extremely high tax rates—as high as 90%, in some cases, of corporation’s “excess profits.”

Many of these World War II policies were informed by Americans' experience during the First World War when “war profiteering” by some U.S. industrial companies became a major scandal after the conflict ended. Similar public anger might be directed at companies this time around that are found to have minted money by over-charging states for essential medical supplies while people die and the overall economy tanks. New York State has, according to a ProPublica investigation, paid almost $250,000 for a portable X-ray machine that normally costs between $30,000 and $80,000 and 20 cents for gloves that normally cost less than five cents.

Sharing IP

Another lesson from Second World War industrial policy, according to historians, is that government should rely on existing products and manufacturers, working with them to expand production through the licensing of their designs to other manufacturers—and not waste time trying to design or invent new devices. David Edgerton, a history professor at Kings College London and author of the book Britain’s War Machine, says that while the war effort did inspire innovation, most of these new technologies took years to be perfected and were not ready for use until near the war’s end. “World War II was largely fought with pre-World War II technology,” he says.

Often, government pressured the original patent holders and designers to license their products to other manufacturers. For instance, Pratt & Whitney aircraft engines were produced under license by the Studebaker Corporation, as well as by factories in the Soviet Union, and British Rolls-Royce Merlin aircraft engines were produced in the U.S. under license by the Packard Motor Company.

Edgerton worries that contemporary policymakers have fallen for the myth, which he said also afflicted U.K. Prime Minister Winston Churchill during the war, that new technology can somehow magically go from drawing board to deployment in mere days, when in reality that process, even during wartime, took years. “Most procurement in the Second World War was ramping up the production of things already being procured,” he says.

To meet the current surging demand for ventilators, the British government initially tried to convince manufacturers who expressed interest in making the devices to create a brand new design. Dyson, best known for vacuum cleaners and hair dryers, has, in fact, created an entirely new ventilator in just 10 days—but now it has to get regulatory approval for its device, a process that may delay its deployment. Other manufacturers balked at the government’s suggestion and, instead, have agreed to license designs from existing ventilator makers.

The myth of retooling production

Another myth from World War II that historians say may stymie current efforts to fight the coronavirus is the idea that a large number of factories were retooled to produce weapons. While some assembly lines were, indeed, reconfigured—for instance, General Motors plants stopped making civilian cars and started making trucks for the U.S. Army, and some brass fittings factories produced bullet casings—Wilson says most key weapons were produced in brand new factories, built at government expense, and then operated under contract by corporations. That, he says, is how most aircraft, tanks and ships for the war were produced.

But, of course, building brand new factories takes months. And the coronavirus outbreak is expected to peak within weeks. So parallels to the Second World War production efforts may be superficial, Edgerton says. “The analogy would have to be with particular events in World War II” — say the way civilian vessels were used in the evacuation of Dunkirk — “rather than the entire war effort.”

Mark Harrison, an economic historian at the University of Warwick in England, agrees. Writing on his blog, Harrison says that the fact governments have had at most just a few months to gear up for the coronavirus pandemic is a big difference from the Second World War, in which governments had spent years before the war’s outbreak thinking about how they might organize society to fight it—plus they had the relatively recent experience of the First World War to learn from. “Here we are in the middle of our war with a blank sheet of paper,” Harrison writes of the COVID-19 outbreak.

One area where there might be time to invest in brand new facilities is in the production of pharmaceuticals, Wilson says. The scale at which vaccine doses in particular will need to be produced may strain existing capacity. And, with a vaccine likely at least a year away, the government could invest now in constructing new facilities and contract their operation out to existing drug manufacturers.

When it comes to macro economic policy, historians say there aren’t many parallels with the current crisis. Harrison writes that World War II caused an explosion in demand—for both capital and labor. As a result, many government policies were targeted at controlling inflation. That’s not true today, with many businesses closed due to social distancing measures and millions of people out of work.

The current situation, Wilson says, actually more closely parallels the Great Depression. And it might require similar programs to help keep people employed, and bolster demand. Wilson says the U.S. might consider taking a page from President Franklin Roosevelt’s New Deal policies and invest in infrastructure projects—just to get people working again. But, on the other hand, he acknowledges, the need for social distancing at the moment argues against policies that would see a lot more people going to work.

The coronavirus is likely to exacerbate Western societies already accelerating income inequality, the historians fear. The Second World War “killed, injured, and bereaved millions, but no one was cast into destitution because everyone had a role, and could find a job,” Harrison writes. “After the war, British society was a lot more equal than before.”

That’s not likely to be the case this time around.