新冠疫情首先是人类的一场大灾难,但它同时也让我们发现了之前被隐藏的瓶颈,暴露出全球系统和供应链的不堪一击。

数据共享和盟友外包这两项措施有望让这些系统重回正轨,同时可以解决我们目前以及未来可能面临的全球环境、经济、政治和社会问题。

数据共享为供应链协作奠定基础

随着与数据共享等问题有关的基本协议付诸实施,国际协作将日益活跃。全世界每个地区都有不同的专业领域,通过协作,不同地区有机会从其他国家的知识中受益。

例如,美国公司和监管机构能够借鉴欧洲同行在工业领域的经验教训,研究欧盟的《通用数据保护条例》(General Data Protection Regulation)或物联网安全标准等规定的产生过程,以确保更好地保护数据隐私。

再来看一下另外一个国家的例子。德国公布的2020年汽车出口量约占其总产量的64%,遥遥领先于其他欧盟国家。德国在物联网、智能数据以及制造和供应链过程分析等方面的大量知识,帮助其他关键工艺完成了数字化改造,比如新冠疫苗的生产。

利用在制造、医疗保健等特定领域的专业知识解决普遍问题,证明了优先考虑成果而不是竞争的价值,以及重视行业发展而非一家公司成败的重要性。

盟友外包是一种新型在岸外包

各国还可以通过建立战略关系,优化贸易和供应链等。盟友外包又称朋友外包,是指从拥有类似价值观和同样承诺透明国际贸易的国家采购必要商品和服务的做法。

与将制造业务转移回国内的在岸外包类似,盟友外包作为支持经济发展和应对外国生产成本日益上涨的一种途径,在最近几年开始流行。事实上,美国的乔·拜登政府在2021年6月发布的一份评估供应链漏洞的报告中,明确表态支持盟友外包,并提出了相关执行策略。

不过将一个模拟过程从一个地方搬到另一个地方,并不能够解决根本问题。这只是掩盖了实际问题:长期以来,供应链因为数字化水平不高而饱受困扰。但把业务转移到同样承诺数字转型、数据主权和开放标准的地区,将从根本上推动供应链迈入数字化时代。

各国携手恢复供应链的正常运行,合作生产新兴行业的高科技产品,不仅可以重建破裂的联盟,甚至能够建立全球经济和数字领导力。这样一来,美国及其盟友可以提供更可行的替代选择,取代有些国家别无选择只能采用的其他技术和经济模式。

美国与欧盟盟友在汽车与出行行业的贸易有30%是半成品贸易。合作生产模式尤其适合生产电动汽车和其他新型出行产品。在这种模式下,各国合作进行产品生产。盟友外包还可以在危机时期大显身手,例如目前的半导体短缺或苏伊士运河堵塞事件等。苏伊士运河堵塞导致价值约96亿美元的货物滞留。

虽然欧洲和美国汽车厂商之间确实存在竞争,但双方通过合作能够降低生产成本和缩短上市时间。之后他们或许会在消费者层面存在竞争,但他们确信他们在经济甚至环境和社会方面变得更具有可持续性。聪明人互相合作,可以取得伟大的成果。

全球经济体构建传播相同市场价值观和行业领导力的联盟已经取得了显著进展,但在国际协作方面仍然任重道远。全球市场必须克服对数据共享的担忧和竞争心态,才能合作应对我们共同面临的挑战。(财富中文网)

本文作者桑贾伊·布拉马瓦尔是企业软件公司Software AG的首席执行官。

译者:刘进龙

审校:汪皓

新冠疫情首先是人类的一场大灾难,但它同时也让我们发现了之前被隐藏的瓶颈,暴露出全球系统和供应链的不堪一击。

数据共享和盟友外包这两项措施有望让这些系统重回正轨,同时可以解决我们目前以及未来可能面临的全球环境、经济、政治和社会问题。

数据共享为供应链协作奠定基础

随着与数据共享等问题有关的基本协议付诸实施,国际协作将日益活跃。全世界每个地区都有不同的专业领域,通过协作,不同地区有机会从其他国家的知识中受益。

例如,美国公司和监管机构能够借鉴欧洲同行在工业领域的经验教训,研究欧盟的《通用数据保护条例》(General Data Protection Regulation)或物联网安全标准等规定的产生过程,以确保更好地保护数据隐私。

再来看一下另外一个国家的例子。德国公布的2020年汽车出口量约占其总产量的64%,遥遥领先于其他欧盟国家。德国在物联网、智能数据以及制造和供应链过程分析等方面的大量知识,帮助其他关键工艺完成了数字化改造,比如新冠疫苗的生产。

利用在制造、医疗保健等特定领域的专业知识解决普遍问题,证明了优先考虑成果而不是竞争的价值,以及重视行业发展而非一家公司成败的重要性。

盟友外包是一种新型在岸外包

各国还可以通过建立战略关系,优化贸易和供应链等。盟友外包又称朋友外包,是指从拥有类似价值观和同样承诺透明国际贸易的国家采购必要商品和服务的做法。

与将制造业务转移回国内的在岸外包类似,盟友外包作为支持经济发展和应对外国生产成本日益上涨的一种途径,在最近几年开始流行。事实上,美国的乔·拜登政府在2021年6月发布的一份评估供应链漏洞的报告中,明确表态支持盟友外包,并提出了相关执行策略。

不过将一个模拟过程从一个地方搬到另一个地方,并不能够解决根本问题。这只是掩盖了实际问题:长期以来,供应链因为数字化水平不高而饱受困扰。但把业务转移到同样承诺数字转型、数据主权和开放标准的地区,将从根本上推动供应链迈入数字化时代。

各国携手恢复供应链的正常运行,合作生产新兴行业的高科技产品,不仅可以重建破裂的联盟,甚至能够建立全球经济和数字领导力。这样一来,美国及其盟友可以提供更可行的替代选择,取代有些国家别无选择只能采用的其他技术和经济模式。

美国与欧盟盟友在汽车与出行行业的贸易有30%是半成品贸易。合作生产模式尤其适合生产电动汽车和其他新型出行产品。在这种模式下,各国合作进行产品生产。盟友外包还可以在危机时期大显身手,例如目前的半导体短缺或苏伊士运河堵塞事件等。苏伊士运河堵塞导致价值约96亿美元的货物滞留。

虽然欧洲和美国汽车厂商之间确实存在竞争,但双方通过合作能够降低生产成本和缩短上市时间。之后他们或许会在消费者层面存在竞争,但他们确信他们在经济甚至环境和社会方面变得更具有可持续性。聪明人互相合作,可以取得伟大的成果。

全球经济体构建传播相同市场价值观和行业领导力的联盟已经取得了显著进展,但在国际协作方面仍然任重道远。全球市场必须克服对数据共享的担忧和竞争心态,才能合作应对我们共同面临的挑战。(财富中文网)

本文作者桑贾伊·布拉马瓦尔是企业软件公司Software AG的首席执行官。

译者:刘进龙

审校:汪皓

The pandemic has first and foremost been a human disaster, but it has also exposed the fragility of global systems and supply chains by uncovering hidden bottlenecks.

Data sharing and ally-shoring are two measures to get these systems back on track and to help tackle the worldwide environmental, economic, political, and societal issues we face now and in years to come.

Data sharing sets the stage for supply chain collaboration

International collaboration comes to life once basic agreements on issues like data sharing are put in place. Every part of the world has different fields of expertise—and there is a tremendous opportunity to benefit from the knowledge of our international counterparts.

For example, U.S. companies and regulatory bodies can learn from their European peers in the industrial domain and look at the development of rules like the EU’s General Data Protection Regulation (GDPR) or IoT (internet of things) security standards to ensure more robust data privacy.

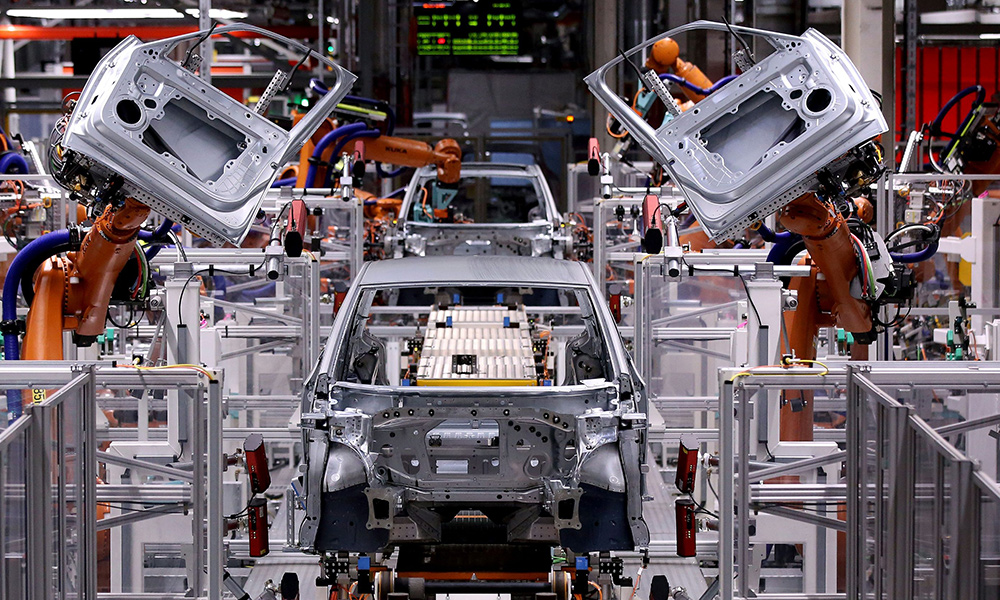

Pulling from another international example, Germany reported that automobile exports accounted for almost 64% of its production in 2020, making it the EU’s leader in that field. This extensive knowledge of the internet of things, smart data, and process analytics for manufacturing and supply chain helped to digitize other critical processes such as the COVID-19 vaccine rollout.

The practice of applying specific domain expertise—whether it’s in manufacturing, health care, or other areas—to universal problems shows the value of prioritizing outcomes over competition, the elevation of an industry over the success of an individual company.

Ally-shoring is the new onshoring

Countries can also build strategic relationships to optimize trade, supply chains, and more. Ally-shoring, a.k.a. friend-shoring, is the practice of sourcing essential goods and services from countries that share similar values and a commitment to transparent international trade.

Like onshoring—the movement of manufacturing back within domestic borders—it has gained ground in recent years as a way to support the economy and circumvent rising foreign production costs. In fact, the Biden administration demonstrated support for ally-shoring and proposed tactics to achieve it in its June 2021 report, which assessed supply chain vulnerabilities.

Moving an analog process from one place to another doesn’t correct the underlying issue. It only papers over the cracks of the real problem: Supply chains have long suffered from a lack of digitalization. However, locating operations in parts of the world that share a similar commitment to digital transformation, data sovereignty, and open standards will make a fundamental difference in moving supply chains into a digital age.

By working together to rewire supply chains and coproduce high-tech products in emerging sectors, countries will not only be able to rebuild bruised alliances, they can even establish global economic and digital leadership. In doing so, the U.S. and its allies can provide more viable alternatives to other technological and economic models that some countries have little choice but to adopt.

In the automotive and mobility sector, 30% of the U.S.’s trade with EU allies is in intermediate goods. A coproduction model in which countries make products together will be especially effective for electric vehicles and other emerging mobility products. Ally-shoring can also be beneficial in times of crises, such as the ongoing semiconductor shortage or the Suez Canal blockage which held up an estimated $9.6 billion of goods.

While European and U.S. car manufacturers do compete for the same buck, both sides can reduce their costs of production and time to market by cooperating. They may then compete at the consumer level, but they do so knowing they are more sustainable in an economic sense—and potentially in environmental and societal senses as well. When smart people work together, great things can be achieved.

Global economies have taken significant steps toward forging alliances that spread common market values and industrial leadership, but there is more work to be done in terms of international collaboration. Data sharing concerns and competitive mindsets must be overcome for global markets to partner on mitigating universal challenges.

Sanjay Brahmawar is the CEO of Software AG, an enterprise software company.